Zone Refinement

Zone refinement is the process by which an element can be purified or doped with impurities. The involved materials are melted to a temperature and subjected to pressure based on the previously discussed phase diagrams. At the desired point, they may then be mixed in the case of doping of semiconductors. A seed crystal will be inserted in order to provide a basis for the structure to crystallize around.

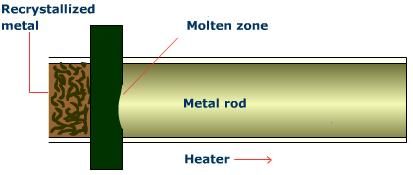

An induction heater will be passed across the material along with the crystal seed in order to align the molecules in the desired fashion. At the end of the process, the concentrated impurities will be left suspended together for easy removal. This process can be repeated multiple times in order to reach the desired purity level. The term “zone refinement” is used because there is a zone of molten metal that moves throughout the bar of metal.

In the below phase diagram, pure forsterite is shown to have a melting point of about 1900C. Pure fayalite melts at 1205C. The solution zone on the graph shows the temperature and concentrations which will result in the ability to refine out one of the silicates.

Member discussion