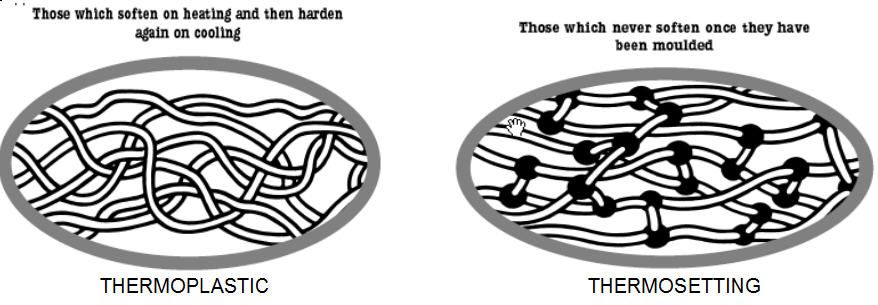

Thermoplastic vs Thermoset Polymers

Thermoplastic and thermoset polymers are the two types of plastics. Plastics are characterized by being polymers of a high molecular mass. They are sometimes augmented with other substances to achieve a particular desired property. Plastics are formed primarily by three different processes: condensation, polyaddition, and cross-linking. Plastics can be further divided into ultra-polymers, high-performance polymers, mid-range polymers, and commodity polymers.

Thermosetting polymer plastics are characterized by strong bonds that are not altered by heat. These must be cured either by an irreversible heat process, radiation, or a chemical reaction. Once a thermoset plastic has been molded, it will remain in that shape. It will be far more likely to undergo brittle fracture than plastic deformation or ductile failure. These plastics are used in epoxies, countertops, plates, adhesives, furniture, and many other applications. They are typically stronger than thermoplastics and also have better thermal performance. They are typically non-recyclable.

Thermoplastic polymer plastics are those which have weak bonds that will reform after heat breaks them. These plastics will soften as heat is applied but typically return to approximately the same shape upon cooling. These are used in many applications such as soda bottles, food containers, computers, safety glasses, CDs, and many others. These are more likely to undergo ductile failure but still may undergo brittle fracture. Thermoplastics are typically more lightweight. They also are recyclable. Unfortunately, they are susceptible to melting as the name would indicate. Also, thermoplastics are typically less expensive than their thermoset equivalent.

Member discussion