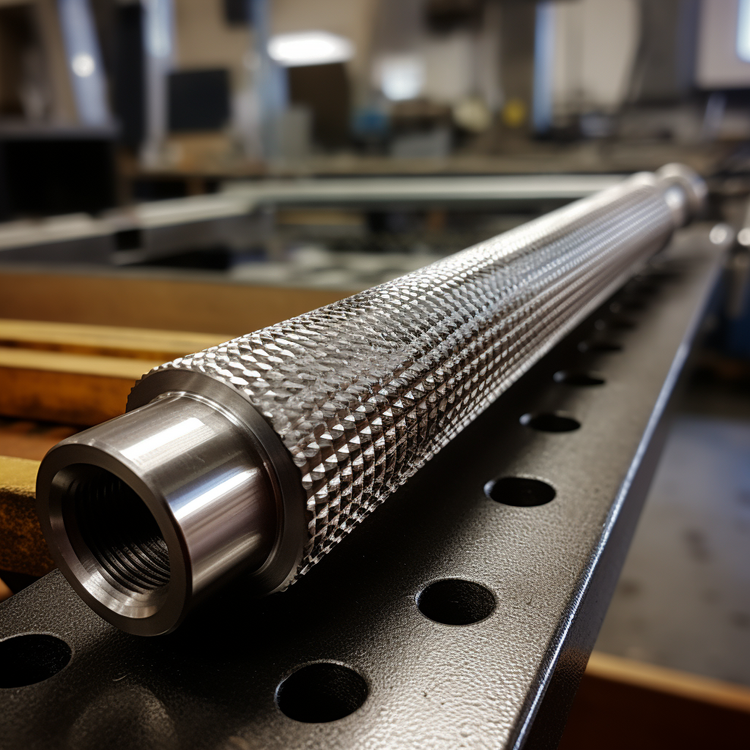

Design for Manufacturing: Knurling

Knurling is the process by which repeated patterns are cut or rolled onto a material. Normally this is accomplished on

Design for Manufacturing: Grinding

Grinding is a subtractive process that utilizes an abrasive wheel to remove material from a workpiece. Design engineers must remain

Design for Manufacturing: Gang Milling

This article looks at the time and tooling considerations behind gang milling.

Gang milling is the process by which multiple

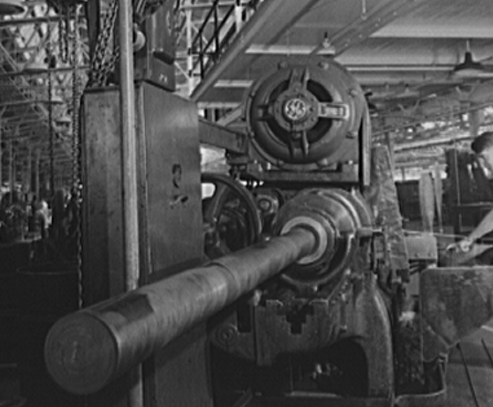

Design for Manufacturing: Secondary Operations on Rods

This rule involves the minimization of secondary machining operations on extruded rods cut from bar stock.

Extruded rods are frequently

Design for Manufacturing: Shaft Keyways

Keyways are cut into shafts to connect them to another object. Typically, this transmits rotational energy by providing a transmission

Design for Manufacturing: Drilling Surface Requirements

This article considers the requirements for drilling surfaces in the context of minimizing manufacturing flow times and costs.

Drill entry

Design for Manufacturing: Laser Cutting

Carbon dioxide laser cutting beams are frequently used throughout manufacturing to provide precision cut sheets of material. Laser cutters are

What is Chromatography?

Chromatography (Latin for the study of color) is the process by which a substance can be separated into individual parts

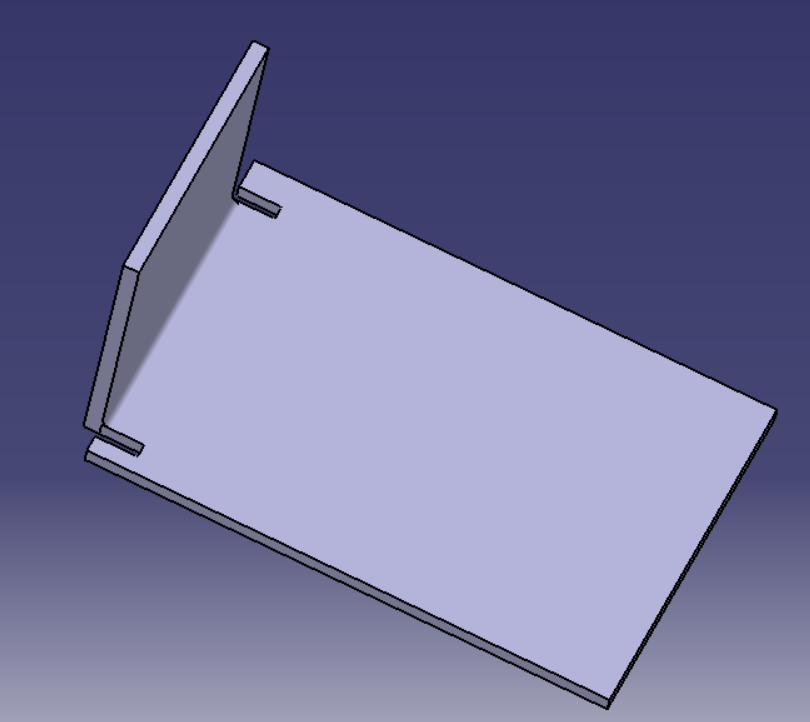

Design for Manufacturing: Sheet Metal Bend Reliefs

Sheet metal is frequently used in building both products and manufacturing machinery. Improper bending of sheet metal can cause material

Design for Manufacturing: Sheet Metal Bending Maximums

This article provides instructions on maximum bend angles associated with stamping operations whenever working with sheet metal.

Each time a