Design for Manufacturing: Sheet Metal Bending Maximums

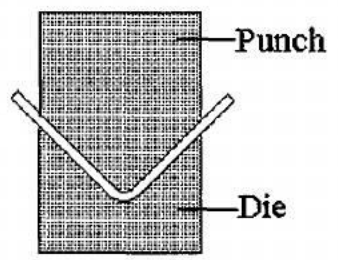

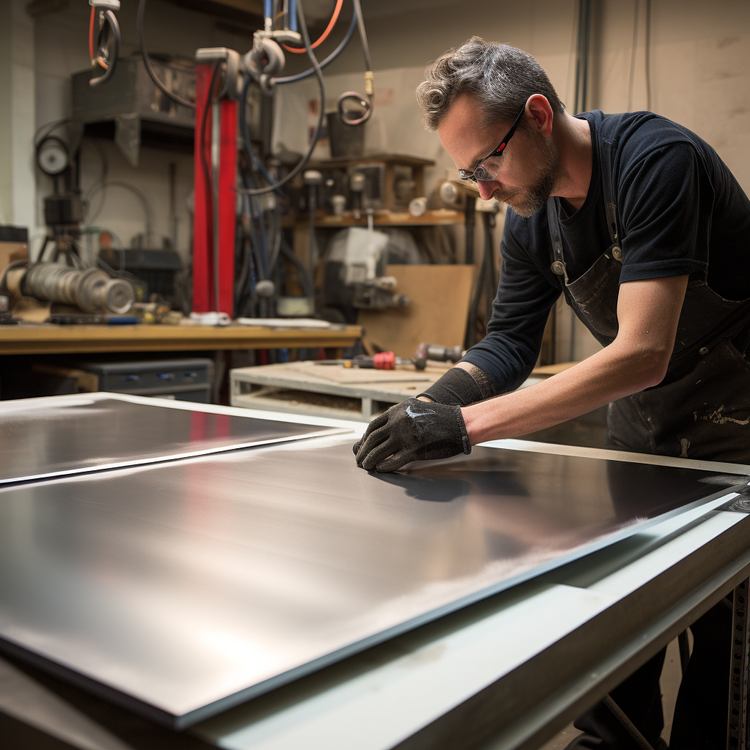

This article provides instructions on maximum bend angles associated with stamping operations whenever working with sheet metal.

Each time a part is bent, it requires tooling to do so. The process where bending is accomplished such that a particular angle must be greater than 90 degrees is called over-bending. Unfortunately, over-bending is not a desirable trait for a part to have. Over-bending significantly complicates the required tooling, as at least two bending operations will be required. Generally, this is accomplished by bending the part to 90 degrees and then bending to the remainder of the way in a separate operation.

Some commercial options are available that can accomplish this in a single operation; however, they are proprietary and must be individually licensed. These methods typically involve special rocker arms and roller assemblies, which allow the part to be manipulated while being pressed.

If

(a) While designing a product that will utilize sheet metal

(b) If bending operations are to be performed

Then

(a) Avoiding bend angles of over 90 degrees should be prioritized whenever possible

(b) If bend angles of over 90 degrees are required, multiple bending operations will be necessary

(c) The first bending operation is called the pre-bend and should allow for spring-back considerations

By following this rule, product designers will require less costly tooling to produce sheet metal parts that incorporate bending operations. Flow time will also be reduced as fewer operations are required if no bends are greater than 90 degrees in the final product.

Member discussion