SysML Feature Set

SysML makes use of nine primary diagram taxonomies in its graphical modeling language. The package diagram allows for the representation of model elements. This provides a clear overview of the organization of the model. Requirement diagrams allow for an explanation of requirements along with the requirement hierarchy throughout the product. Requirements are text strings that qualitatively describe the product. Activity diagrams demonstrate the product behavior based on input/output sequences. This is similar to state machine diagrams, except state machine diagrams are based on event-driven state transition [1].

Sequence diagrams demonstrate the message exchange in a given system. Use case diagrams allow for stating the system functionality of external systems. Block diagrams allow for structural composition (both internal and external) to be defined. This also allows for showing the hierarchy of components. In the case of internal block diagrams, system interrelations and internal interfaces will be described. Parametric diagrams clearly define constraints in terms of other parameters [1].

For example, consider a typical pneumatic tool air compressor. This system could be broken down using SysML. The package diagram would contain the air compressor requirements, behavior, structure, and parametric properties. The requirements would be further broken down into the specifications for the air compressor. The requirements would include the power requirement, air compression rate requirement, maximum pressure requirement, portability, flow rate, relative reliability, and storage capacity.

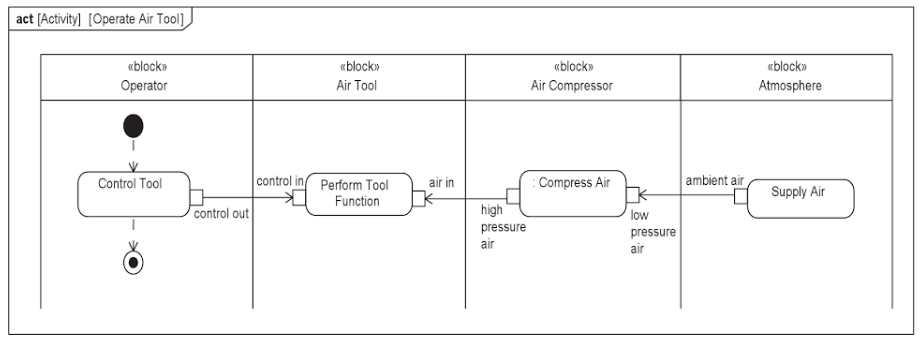

The activity diagram for the air compressor's behavior (shown above) shows the expected operation of an air tool connected to the air compressor. All interactions are defined, including the air compressor's suction of the atmosphere. The air compressor's primary function is to compress air as a service for the air tool.

The actual structure of the air compressor can be easily described using a hierarchical block diagram. The air compressor uses a motor controller, a motor, a pump, and a tank to achieve a complete compression and storage cycle. These items ultimately achieve the objective of attaining a specified air flow rate out of the compressor.

From a parametric standpoint, the air compressor receives a given flow rate from several constraints. The constraints are the tank's volume, the differential pressure across the vessel compared to the atmosphere, the power of the motor, the efficiency of the air pump system, and the airflow rate provided based on the command speed from the motor controller [1]. These parameters can be parametrized for use in either SysML modeling or imported into an axiomatic design matrix as design parameters [2].

References:

[1] Freidenthal, S., Moore, A., Steiner, R., 2012, A Practical Guide to SysML: The Systems Modeling Language, Elsevier Ltd, Amsterdam.

[2] Suh, N. P., 1995, "Axiomatic Design of Mechanical Systems," J. Mech. Des., 117(B), p. 2.

Member discussion