Automated Fixture Design Processes

Automated fixture design processes are an innovative method to reduce the workflow time necessary to create vital tools for manufacturing. Automated fixture design is typically called computer-aided fixture design (CAFD) and involves using one or more expert systems. Computer-aided fixture design will continue to be developed by manufacturers to meet consumer demand for low-price manufactured goods better.

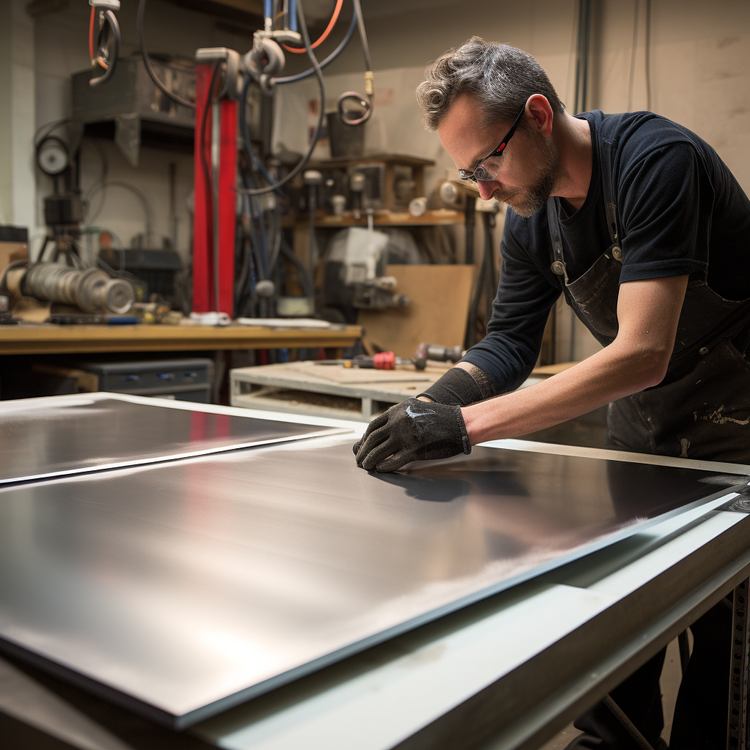

Fixtures are tools that position a workpiece in a particular location and orientation to allow for machining or other work. Fixtures are typically designed to hold a workpiece to restrict at least one direction of rotation or translation. In an ideal fixture, all axes and directions of rotation are constrained. Typical fixtures are designed with planned clamping points, locator pinpoints, and support points. Automated fixture design may be used to expedite the selection of these points.

Artificial intelligence usage in computer-aided fixture design takes many potential forms [1]. Most expert systems function by utilizing the expected geometry of the fixture. These automated systems will typically identify the locating and clamping faces for the fixture based on the major and minor faces as determined by relative size. Some fixture design software selects components based on a modular design approach where groups of components are considered rather than discrete components.

Forces involved in clamping may be considered. Overall forces applied may be described individually or in a single free-body diagram. Alternatively, forces may not be described at all. Forces may be regarded strictly for tipping purposes, with little attention to deformation. These design decisions depend on the particular algorithm chosen by the design engineer. If the engineer initially ignores required forces, the fixture analysis design stage must compensate to meet overall design tolerances.

More promising developments in a total design solution have been realized by integrating algorithm- and heuristics-driven methods. This system also uses geometric inputs like many others but also considers reference geometry and tool layout model requirements. This solution combines stress analysis into the software package. As a result, industry-standard software is trending towards complete packaged solutions.

Future trends indicate a shift towards integrating large, packaged algorithm bundles and modular fixture design integration. Indexed searching of extensive databases is becoming more commonplace as computing power grows. Newly developed genetic algorithms and neural networks allow for fast cross-referencing between datasets. Alternatively, some algorithms promote the accessibility of a particular location to be weighted more heavily. These algorithms receive geometric input and calculate relative ease of access to determine fixturing clamping locations. In addition, some consideration is given to fixture stability and stress. Further out, it can be expected that integrating multiple selection algorithms using both heuristics and geometric selection criteria will be used for future fixture design and feature integration.

References:

Cecil, J., (2001), "Computer-Aided Fixture Design - A Review and Future Trends," International Journal of Advanced Manufacturing Technologies, 18, pp. 790-3.

Member discussion