High Temperature Ceramics

Ultra-high temperature ceramics are ceramics that can undergo temperature, chemical, and erosive extremes and still reliably perform their purpose. In the case of ceramics, extreme temperatures are considered to exist at around 3000C.

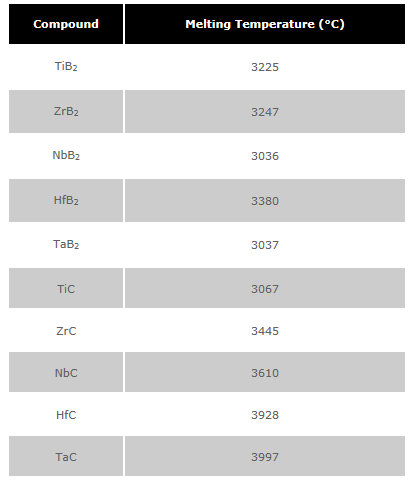

This table provides an example of ceramics with high-temperature resistance.

These materials form two primary groups: borides and carbides. Borides typically have a flex strength of 300-500MPa at room temperature. When mixed with other materials, they can double that. However, as the temperature is increased, a lower strength will be observed. One manufacturing process to date has shown strength retention up to 1500C. That process is called “spark plasma sintering.”

Sintering is the process by which a ceramic is held just below the melting point to allow the ceramic powder to adhere to each other. Tiny pores will be formed initially, but as the process continues, the pores will close up or disappear entirely. This will lead to a much higher mechanical strength.

Spark plasma sintering is similar, except an electrical current is applied instead of a furnace. Plasma arcs will jump from each ceramic particle to another, which will heat them to several thousand degrees Celsius.

As each particle adheres to the other, a current will flow. This current generates more heat through thermal losses, which will finish the heating process. Finally, the material will undergo plastic deformation under uniaxial stress in the die. Implementing this is a complicated process as the direct current generator is costly and requires a substantial setup time. Also, only simple symmetrical shapes can be created.

The other type of UHTC is carbides. Carbides typically have a slightly higher melting temperature but are less electrically conductive than borides. Carbides are also somewhat more susceptible to oxidation. However, they are much more resistant to erosion, making them the material of choice for rocket nozzles. Another common problem with carbides is a breakdown temperature in the manufacturing process where density will lower due to grain coarsening leading to pore formation.

Member discussion