Design for Manufacturing: Secondary Operations on Rods

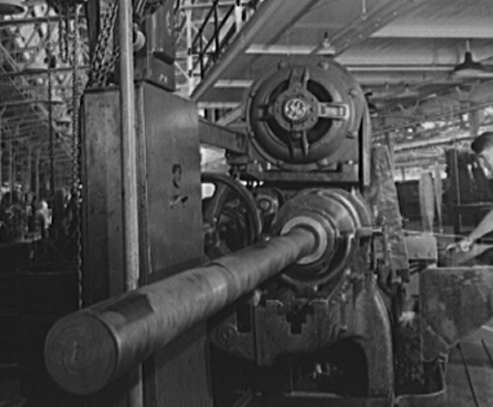

This rule involves the minimization of secondary machining operations on extruded rods cut from bar stock.

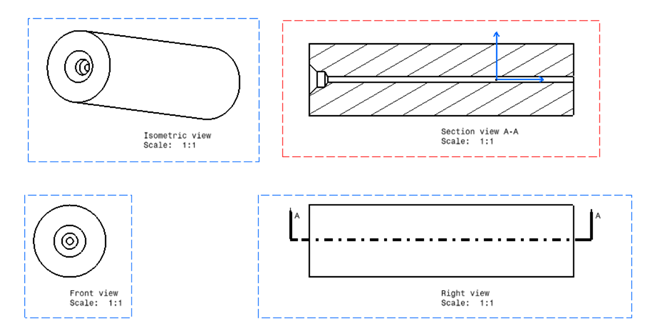

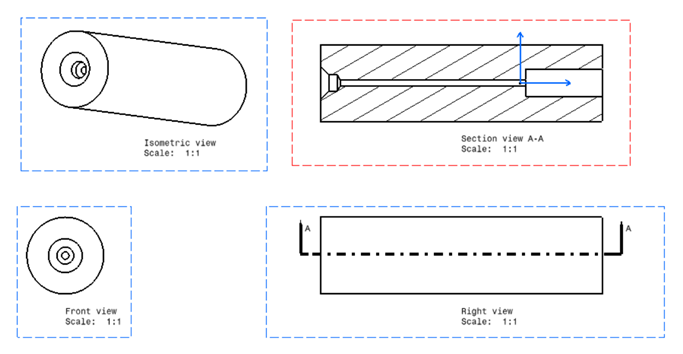

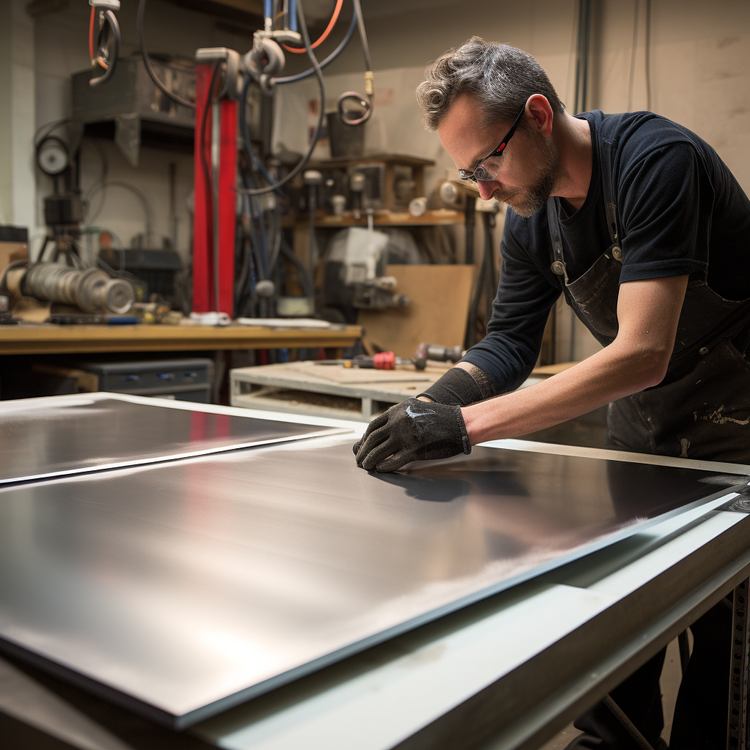

Extruded rods are frequently used to create machined products. These rod segments may be machined while still attached to the extruded rod. In fact, doing so is preferred due to the overall reduction in tooling costs associated with machining the part while still attached. Machining operations that follow cutoff from the extruded rod are considered secondary operations. Secondary operations take the form of screw thread creation, slots, flats, or other machining operations.

One requirement to make it possible to eliminate secondary operations is to ensure that all part features are located on one end of the extruded rod. The rod may be rotated on a lathe if necessary in order to taper a portion or perform grooving.

If

(a) While designing machined parts:

(b) If the parts are being cut from an extruded rod

Then

(a) Design the part to receive all necessary machining prior to being cut from the extruded rod.

(b) Minimize post-cutoff machining operations.

(c) Place features on one side of the rod when possible.

(d) Use lathes to rotate the rod if necessary.

Use of this rule will reduce machining costs and flow times due to minimizing machining operations.

Member discussion